Customization Services For Steper Motor

Custom Stepper Motor

- Coil modification of a resistance, inductance and current

- Stepper motor protection grade

- Reduce or increase magnetic resistance to meet the needs of application

- Special flange interface options

- Motor wire length

- Encoder, brake, built-in drive

- High strength plastics can withstand greater impact

- Customized shaft - metric, British, shaft end processing, shaft diameter, length

- Screw motor custom design scheme

- Brushless motor custom design scheme

- Protection grade for special environment application

- Custom screw -- metric, British, shaft end processing, pitch, length

Customized and Optimized Stepper Motor Solutions

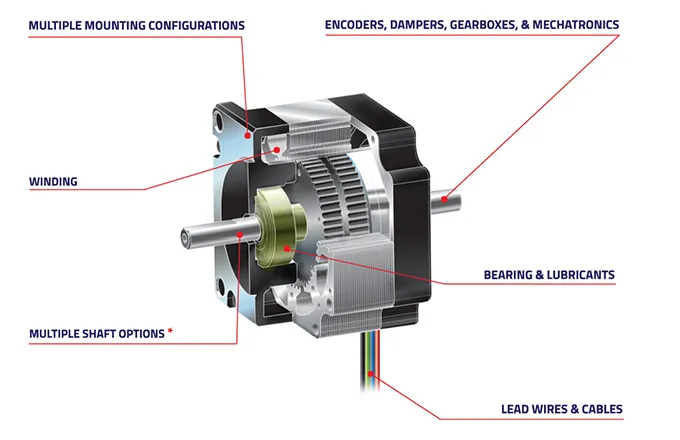

Our expertise lies in our ability to tailor our motors for your unique needs, a standout quality in the industry. We optimize our stepper motors to meet your specific performance requirements, be it boosting torque, reducing noise, or increasing power efficiency.

We can also modify the motor’s structure to fit your assembly perfectly. This includes customizing lead wires, connectors, and brackets, and modifying shafts with gears or pulleys. Furthermore, we can enhance the motor with gearboxes, encoders, dampers, or customized electronics.

Customized Winding Design

- Increase motor’s torque at specific speed output

- Increase motor’s speed at specific torque output

- Reduce motor’s heat generation

- Reduce motor’s noise generation

- Reduce motor’s resonance or vibration

- Optimize motor’s power consumption

- Use special winding material with specific insulation ratings for hot or cold environment operation

Our database consists of thousands of different winding recipes for each series of motors, and therefore we can often hit specific performance targets simply by reaching into our database. In case we do need to create a completely custom winding recipe, we can rapidly prototype and test windings at our facility. Our engineers are based at our Northern California manufacturing facility and have access to the same winding machines that will be used during the production runs of the final product. This allows us to rapidly test various windings to hit the target performance.

Multiple Shaft Options

- Flat shaft

- Helical-cut shaft

- Cross-drilled shaft

- Slotted shaft

- Hollow (pass-through) shaft

- As well as press-fit gears or pulleys

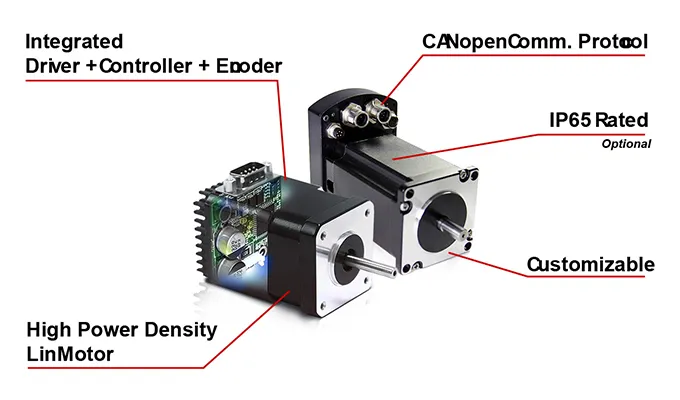

Mechatronic Solutions

Quickstart motors can be fully integrated with custom and proprietary mechatronics components, allowing the system to be precisely tuned to your specific application’s needs. The result is a complete, all-in-one, plug-and-play package that greatly reduces the complexity of your system and makes installation a breeze.

- Quickstart Motors fully integrated with drivers, controllers, and encoders

- State-of-the-art closed-loop system developed in the Switzerland

- Optimized performance for your specific application

- Enhanced torque and speed output

- High efficiency per watt

- Plug-and-play solution

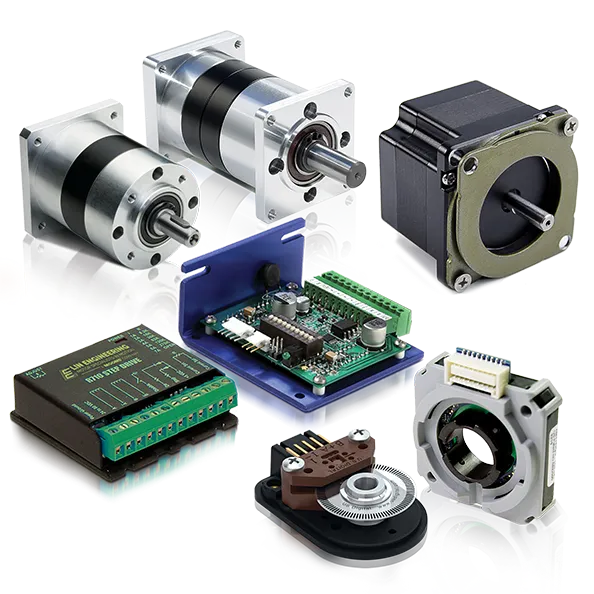

Value Add Services

Quickstart motors can be fully integrated with custom and proprietary mechatronics components, allowing the system to be precisely tuned to your specific application’s needs. The result is a complete, all-in-one, plug-and-play package that greatly reduces the complexity of your system and makes installation a breeze.

- Gearboxes

- Encoders

- Dampers and Brakes

- Drivers and Controllers

Your Reliable Steper Motor Manufacturer

12+ Years of Experience. High Quality and OEM Design. Professional R&D Team. Competitive Price.